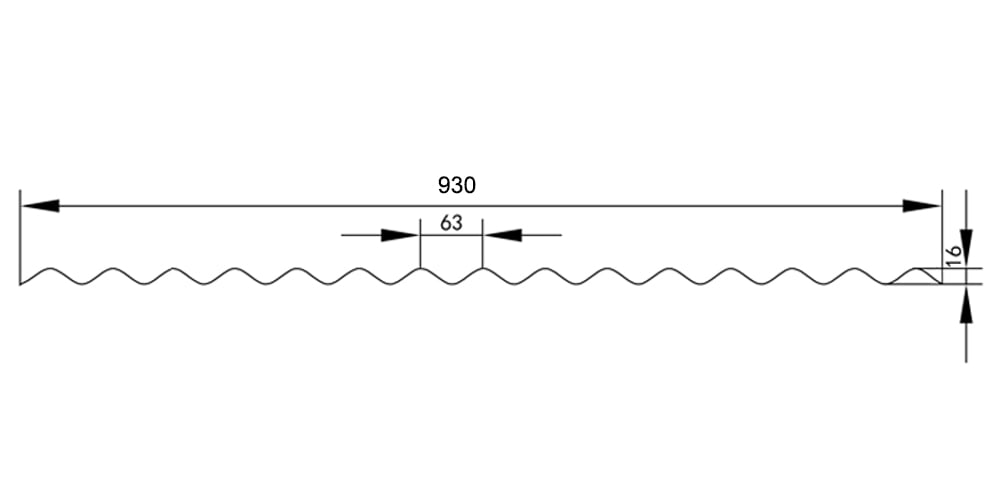

XINGFA Translucent Corrugated PVC P3 Specification

Width: 720mm/930mm/1130mm

Effecived Width: 640mm/830mm/1030mm

Length: Customized

Thickness: 0.8mm,1.0mm,1.5mm,2.0mm

Application: Sheds, Workshops, Parking Lots, Production Workshops, Greenhouses, Farms, Chemical Plants, ect.

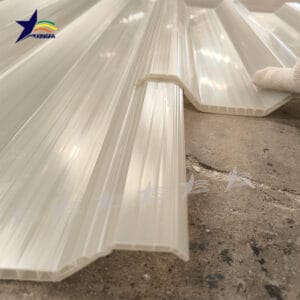

Translucent Corrugated PVC P3

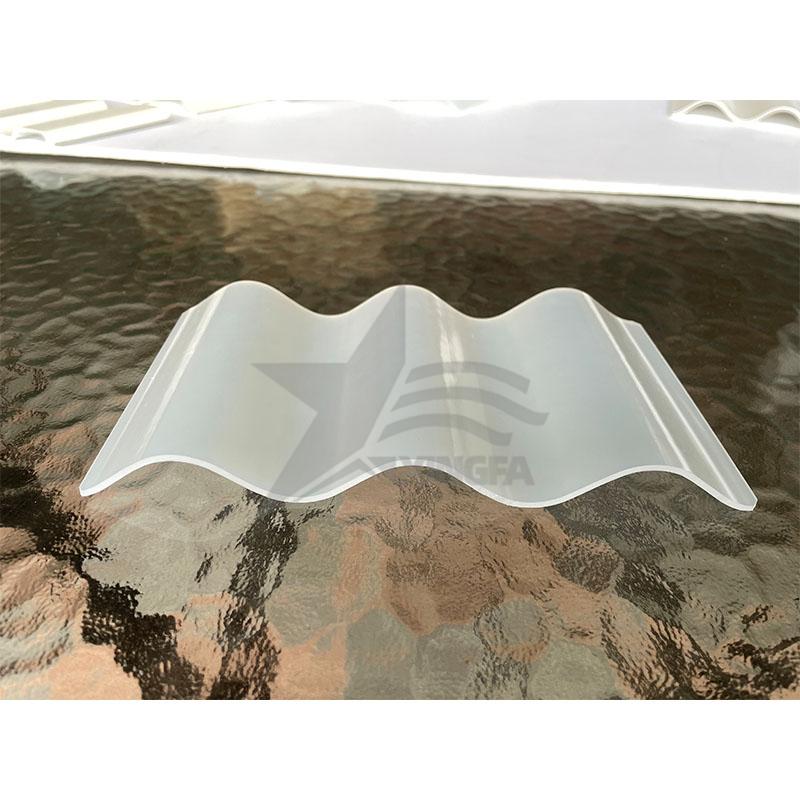

Translucent Roof Sheet Is One Of The Most Popular Profiles In The Xingfa ROOF Product Line, Prized For Its Simple One-Piece Design,

Which Exhibits A Unique Corrugated Pattern On The Roof Surface.

Compared To Clay Roof Tiles, Spanish Colonial Roof Sheet Can Enhance Almost Any Architectural Style.

Play Video

| Test Technical Data from SGS | ||||||||||||||||

| Item | Test Method | Test Condition | Result | |||||||||||||

| Dimension Stability | ASTM D1204-14 | Specimen: 25cm*25cm 100℃, 60min Medium: Talc powder | Direction of Vertical | -0.60% | ||||||||||||

| Direction of Horizontal | 1.60% | |||||||||||||||

| Vicat Softening temperature | ISO 306-2013 method B50 | Heat-transfer meida: Silicone oil Rate of temperature: 50K/h Load: 50N | 77.0℃ | |||||||||||||

| Fire rating | DIN 4102-1:1998-05 | Cotton indicator ignited by flaming particles or drops with V-2 | B2 | |||||||||||||

| Effect of liquid chemicals | ISO 175-2010 | Immersion method Temperature: 23℃ Immersion time: 48h | 40%(m/m)NaOH | No visual change | ||||||||||||

| 35%(m/m)HCL | Visual discoloring, but no other visual change | |||||||||||||||

| 30%(m/m)H2SO4 | No visual change | |||||||||||||||

| Light Ageing Test Xenon-arc Exposure | ISO4892-2:2013cycle4 ISO 105-A02:1993/Cor.2:2005 ASTM D2244-15a | Irradiance:(0.51±0.02)W/(m·nm)@340nm 102 min light at (63±3)℃ BPT, (50±10)% RH 18 min light and water spray Filter: Boro/Boro Exposure Period: 1000h | Grey Scale: 3 △Eab=1.3 | |||||||||||||

| Striker Impacted by a Falling Weight | GB/T 8814-2004 Section 5.7 Section 6.7 | Condition: -10℃ , 1h →Take out and do the test within 10s Strik weight:1000g Height:1000mm Span:200mm No. of specimen tested:10 | breakage:0 | |||||||||||||

| Thermal conductivity | ASTM C518-17 | Condition the test specimen at(23+2)°C and(50+5)% relative humidity to constant mass | 0.09(W/m·K) | |||||||||||||

| Thermal resistance | 0.03(m2·K)/W | |||||||||||||||

| Tensile Breaking strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 20.3Mpa | |||||||||||||

| Tensile Strength | GB/T 1040.2-2006 | Span:115mm Specimen width: 25mm Power: 1050N | 20.63Mpa | |||||||||||||