With the development of industry and the intensification of environmental issues, the selection of building materials for factories has become particularly important. Natural disasters such as acid rain and hail occur frequently, and global temperatures rise. Traditional metal roofing materials have gradually exposed their problems of being prone to corrosion and having poor thermal insulation and heat preservation performance. Against this backdrop, PVC hollow roof tiles, with their unique advantages, have become the ideal choice for factory roof materials.

Firstly, PVC hollow roof tiles have outstanding corrosion resistance. It is made of polyvinyl chloride resin and can remain stable in chemical environments such as salts, alkalis, and acids without undergoing chemical reactions. This characteristic makes it particularly suitable for areas with frequent acid rain, corrosive factories, and coastal regions, effectively resisting the erosion of acid rain and other corrosive substances, and extending the service life of the roof.

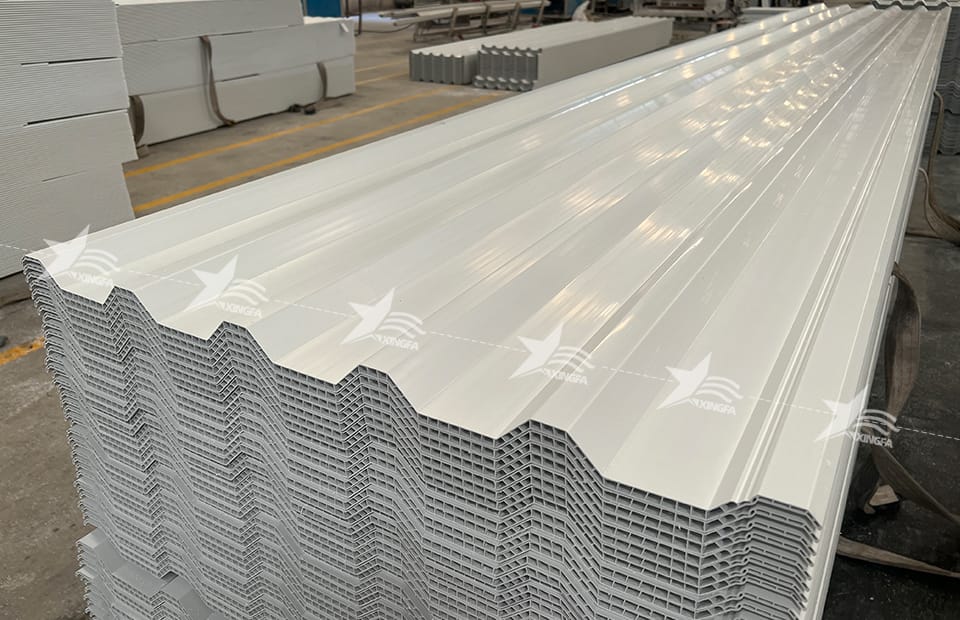

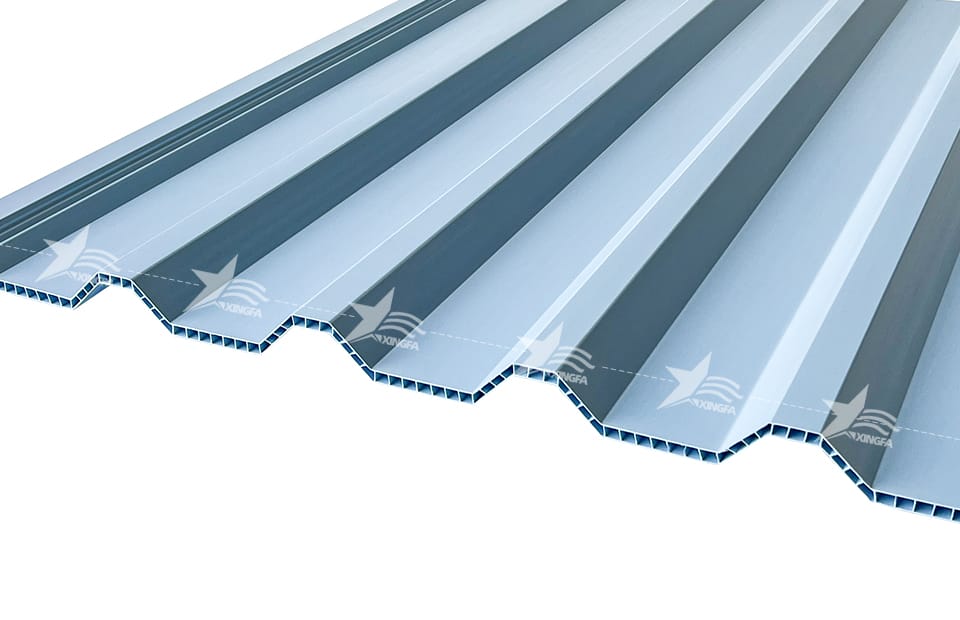

Secondly, the thermal insulation and heat preservation effect of PVC hollow roof tiles is extremely excellent. Its hollow multi-frame structure design, by utilizing the principle of air circulation, achieves excellent heat insulation and reduces the temperature difference between the inside and outside of the factory building. This not only enhances the comfort level inside the factory building, but also reduces the energy consumption for cooling and heating, saving energy costs.

In addition, PVC hollow roof tiles also have excellent waterproof performance. The tiles are designed with anti-seepage grooves, which can effectively prevent rainwater from seeping in, ensuring the dryness inside the factory building and the safety of the equipment. Meanwhile, its sound insulation performance is also excellent, which can significantly reduce external noise and provide employees with a quiet working environment.