As industrialization develops, environmental pollution is becoming increasingly serious. In the industrial field, especially in the chemical industry, corrosion is particularly serious. Most of the raw materials, by-products, products and volatile gases used in the production process have strong corrosiveness, which can cause corrosion damage to the workshop structure, walls and roofs, especially the external walls and roofs of the factory after corrosion, which not only affects the overall image of the factory, but also brings leakage and affects the operation of the factory. In the strong acid rain area along the east coast of China, the losses caused by corrosion cannot be estimated every year. Therefore, it is urgent to solve the corrosion problem of the factory. At present, there is a kind of roof and wall building materials specially developed for the workshop, which has excellent anti-corrosion performance and is specially used to solve the corrosion problem of the workshop roof and wall. In 2020, in fact, most factories are still using PVC plastic tiles.

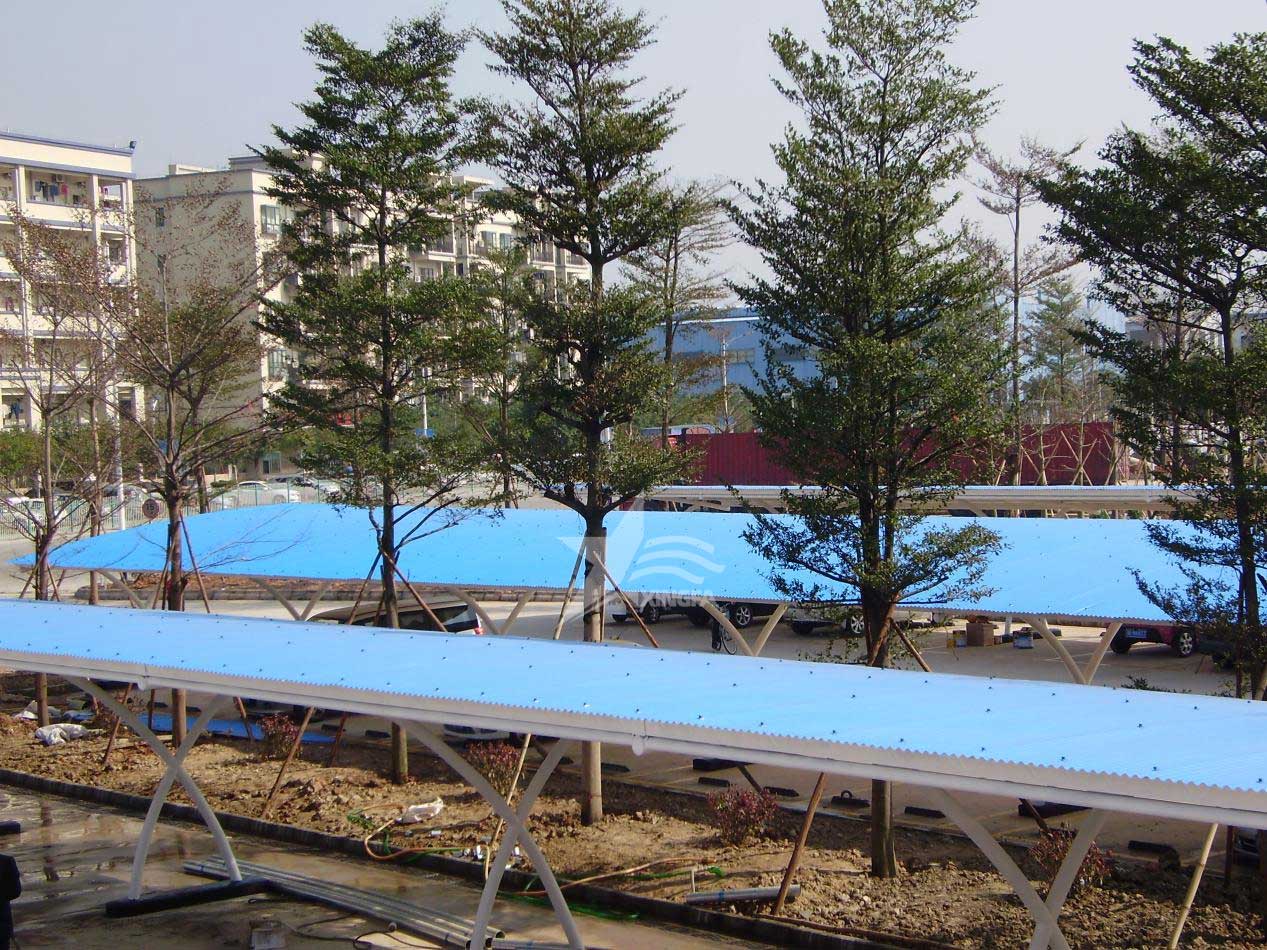

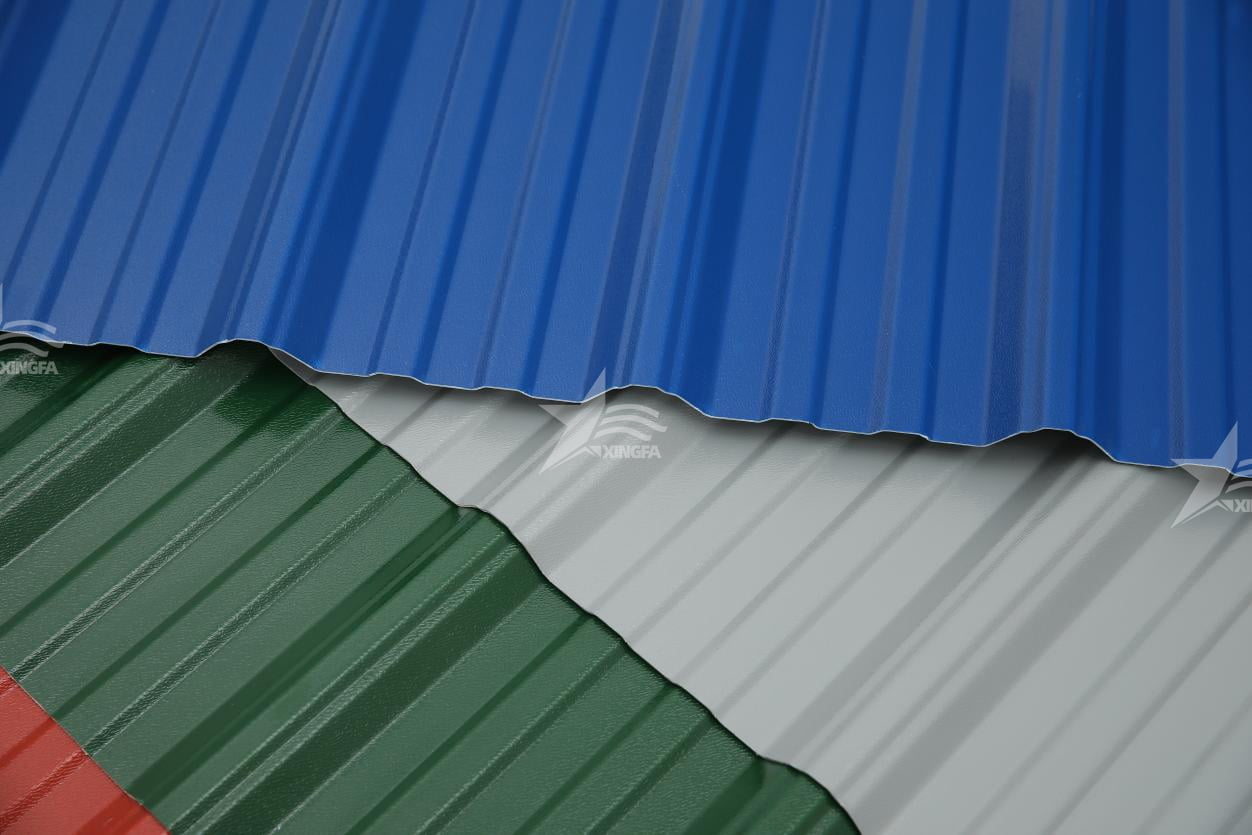

PVC plastic tiles, as the name implies, are not made of iron sheet and will not rust. Experiments have shown that PVC plastic tiles can be soaked in salt, alkali and various acids below 60% for 24 hours without any chemical reaction. It is especially suitable for areas with frequent acid rain, corrosive factories and coastal areas. The advantage of PVC plastic tiles is that they have good corrosion resistance. In addition, its thermal insulation, sound insulation, fire prevention, waterproof, explosion-proof and anti-cracking properties are also very outstanding, and it has become an absolute advantage to replace iron sheet tiles, which is suitable for factories, warehouses, farmers’ markets, passages, garages, etc., as well as breeding farms and other fields.