In recent years, with the continuous development of the construction industry, resin roof tiles have emerged as a new type of environmentally friendly building material, gradually attracting attention and popularity. However, the inferior resin roof tiles on the market have also caused some problems, such as cracking, leakage, and fading, which can be inconvenient and troublesome in people’s lives.

These problems mainly come from two aspects: one is the extensive use of inferior recycled materials in the production of resin tiles, and the other is the uneven expansion and contraction of resin tiles due to improper installation by workers. The use of inferior recycled materials will lead to a reduction in the durability of resin tiles, and roof cracking and leakage may occur within 3 to 5 years. Improper installation by workers can lead to cracking and leakage of resin tiles, posing risks and hidden dangers to buildings.

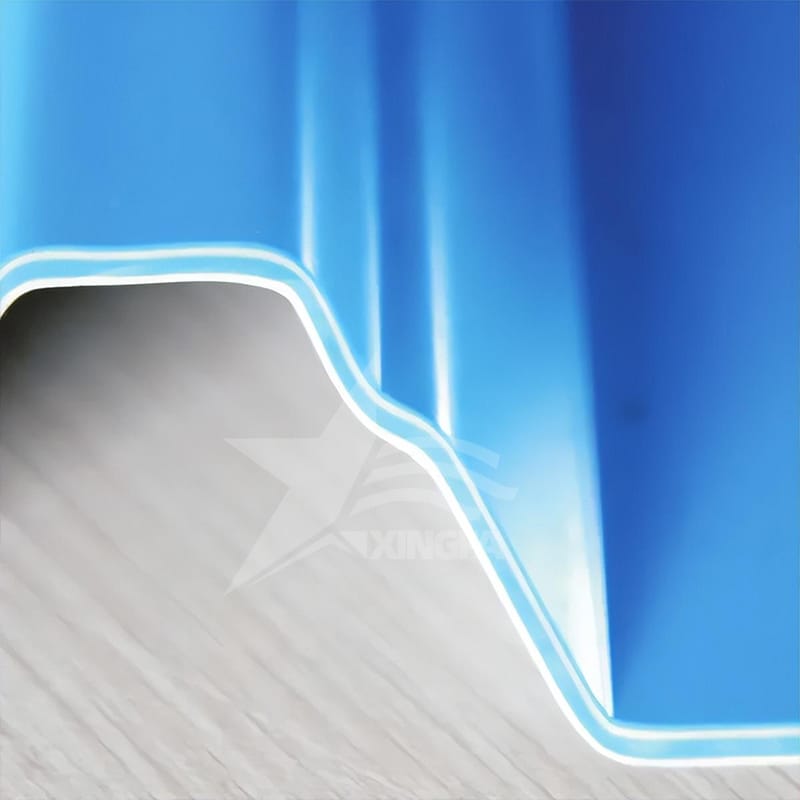

In response to these issues, we recommend that everyone choose ASA synthetic resin roof tiles produced by regular manufacturers. First of all, ASA synthetic resin roof tiles are made from brand-new imported raw materials, ensuring quality. Secondly, through strict production processes and quality control, it is ensured that the product details meet the standards. Most importantly, ASA synthetic resin roof tiles have excellent weather resistance, and their appearance is not prone to fading. They can withstand all kinds of harsh weather conditions and maintain the product’s beauty and functionality for a long time.

A legitimate resin roof tile manufacturer also offers a product quality guarantee of up to 20 years, so consumers can use it with complete confidence.